Hypothesis testing is a crucial statistical tool in Six Sigma, used to validate whether process improvements lead to significant and sustainable benefits. By comparing data before and after changes, businesses can determine whether observed effects are genuine or merely due to chance. This method is integral to the Analyze phase of the DMAIC cycle, ensuring that Six Sigma … [Read more...] about Six Sigma Hypothesis Testing: A Step-by-Step Guide

Quality-LEAN-6 Sigma

Free Resource: All Six Sigma Tools for Quality Management

Six Sigma tools are pivotal in improving business processes, identifying inefficiencies, and ensuring quality management. These tools cater to various needs, from root cause analysis to decision-making and strategic planning. Tools like the 5 Whys and Pareto Analysis are popular due to their simplicity and effectiveness in identifying primary causes of issues. Advanced … [Read more...] about Free Resource: All Six Sigma Tools for Quality Management

Six Sigma Certification: Reasons | Benefits | Cost | Future

Six Sigma certification validates expertise in improving business processes through a structured, data-driven approach. Recognized worldwide, Six Sigma provides professionals with tools like DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify) to optimize quality and efficiency. These methodologies are not limited to a specific … [Read more...] about Six Sigma Certification: Reasons | Benefits | Cost | Future

Top 5 Reasons Six Sigma Fails & How To Overcome the Pitfalls

Despite its reputation as an effective process improvement methodology, Six Sigma can fall short of expectations for several reasons. One of the primary barriers is a lack of buy-in from senior leadership. Six Sigma projects struggle to secure resources, align with organizational goals, or gain traction without the necessary support. Additionally, the time-sensitive nature of … [Read more...] about Top 5 Reasons Six Sigma Fails & How To Overcome the Pitfalls

Using Statistical Process Control in Six Sigma Projects

Statistical Process Control (SPC) is a powerful tool that, when integrated into Six Sigma projects, helps businesses proactively manage quality control, shifting from reactive fixes to preventive strategies. By using data-driven tools such as control charts and Pareto diagrams, companies can detect variations in their processes early, allowing them to address potential defects … [Read more...] about Using Statistical Process Control in Six Sigma Projects

Six Sigma Statistics: Key Metrics for Quality Improvement

Six Sigma statistics are crucial for identifying process variations and making data-driven decisions that lead to continuous improvement. Using statistical analysis, organizations can operate more efficiently and deliver higher customer value. This involves applying key statistical concepts such as descriptive and inferential statistics and essential tools like control charts, … [Read more...] about Six Sigma Statistics: Key Metrics for Quality Improvement

Book Review: Lean Six Sigma Black Belt: Summary Sheets

"Lean Six Sigma Black Belt: Summary Sheets" by Sandeep Kumar is a resource to simplify the journey to Lean Six Sigma Black Belt certification. The book summarizes often complex LSSBB principles. He covers advanced Lean Six Sigma methodologies, including DMAIC and DMADV, and delves into sophisticated statistical tools and problem-solving techniques. Including practical … [Read more...] about Book Review: Lean Six Sigma Black Belt: Summary Sheets

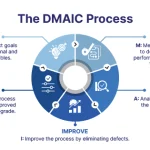

Driving Process Excellence through Six Sigma and A Data-Centric Approach

Six Sigma is a powerful methodology that helps businesses optimize their processes by using a data-driven approach. At the core of Six Sigma is the DMAIC framework—Define, Measure, Analyze, Improve, and Control—which guides organizations through identifying inefficiencies, analyzing data, and implementing solutions. By relying on concrete data, businesses can avoid flying … [Read more...] about Driving Process Excellence through Six Sigma and A Data-Centric Approach

Six Sigma Process Mapping: A Step-by-Step Guide to Enhancing Productivity

Six Sigma is a meticulous, data-oriented methodology designed to enhance business processes by minimizing errors and achieving nearly flawless operations. Process Mapping, a vital element of the Lean Six Sigma approach, provides a visual representation of a process, detailing the necessary steps and components to complete a task within an organization. Acting as a blueprint, it … [Read more...] about Six Sigma Process Mapping: A Step-by-Step Guide to Enhancing Productivity

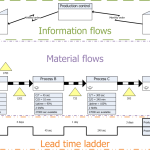

What Is Value Stream Mapping & How Is It Used in Six Sigma

Value Stream Mapping (VSM) is a pivotal tool in Six Sigma, a methodology aimed at improving product quality and efficiency by minimizing errors, variations, and waste. Initially developed in manufacturing environments such as Motorola and later adapted across various industries, including finance and healthcare, VSM is a visual method that analyzes and optimizes the entire flow … [Read more...] about What Is Value Stream Mapping & How Is It Used in Six Sigma

Revolutionizing Efficiency: Exploring Innovative Six Sigma Projects Across Industries

Six Sigma, initially rooted in manufacturing, has transcended its origins to become a universal methodology applied across various industries, all to enhance quality management and foster continuous improvement. This approach, including both Six Sigma and Lean Six Sigma, is dedicated to refining processes, boosting efficiencies, and minimizing waste, ultimately leading to … [Read more...] about Revolutionizing Efficiency: Exploring Innovative Six Sigma Projects Across Industries

Lean Six Sigma: Definition, Principles, and Benefits

For quality professionals and non-quality professionals who may have not delved into Lean Six Sigma (LSS), this article provides a good summary. The LSS methodology combines the principles of Lean (focusing on reducing waste and inefficiency) and Six Sigma (aiming to minimize defects and variations in processes). LSS is described as a data-driven process improvement methodology … [Read more...] about Lean Six Sigma: Definition, Principles, and Benefits

A Benefit Costing Process for Lean Six Sigma Programs

This academic study published in "The TQM Journal," addresses the gap between financial measurement and Lean Six Sigma (LSS) methodologies in process improvement initiatives. The study aims to enhance employee engagement by designing a process and a benefit measuring methodology that aligns with financial metrics and LSS principles, particularly in eliminating waste. The … [Read more...] about A Benefit Costing Process for Lean Six Sigma Programs

The Role of Lean Six Sigma in Driving Sustainable Manufacturing Practices

The article from Frontiers analyzes the intricate relationship between Lean Six Sigma (LSS) methodology and its influence on sustainable manufacturing practices. Amidst the backdrop of an increasingly competitive manufacturing landscape, the study highlights the growing inclination of companies towards innovative methodologies like LSS to bolster their operational efficiency, … [Read more...] about The Role of Lean Six Sigma in Driving Sustainable Manufacturing Practices

Green Lean Six Sigma and Improving Manufacturing Sustainability

The article delves into the pressing need for manufacturing industries to prioritize sustainability alongside operational efficiency due to the evolving competitive landscape, informed customers, and stringent regulations. The study's primary objective was to create a Green Lean Six Sigma (GLSS) framework to enhance operational efficiency while addressing environmental and … [Read more...] about Green Lean Six Sigma and Improving Manufacturing Sustainability

Advancing learning in a lean organization

This article outlines how lean organizations, particularly managers and employees, can use different ways of learning depending on how much is known about problems. These stages include the known, known unknown, and unknown "unknown" stages. The author discusses learning in the context of Lean Thinking, a management philosophy focused on maximizing value and minimizing … [Read more...] about Advancing learning in a lean organization

Six Sigma in Manufacturing | Advantages & Disadvantages

A strategy that reduces errors and defects in manufacturing is called Six Sigma. Organizations use Six Sigma to increase the quality of their products. Innovations in technology have changed the manufacturing industry. Understanding and adapting to these changes allow Six Sigma to advance towards quality improvement. Lean manufacturing works simultaneously with Six Sigma to … [Read more...] about Six Sigma in Manufacturing | Advantages & Disadvantages

ISO 9001:2015 Certification and Lean Six Sigma

ISO 9001 or Six Sigma? What certification should companies adopt to improve their quality management system? ISO 9001 can help organizations achieve a quality management system to cover their departments, suppliers, and employees. Six Sigma presents a series of mechanisms and methods to streamline business operations and curtail organization-wide waste. Although both … [Read more...] about ISO 9001:2015 Certification and Lean Six Sigma

Why a Plan for Every Part Is Essential to Lean Transformations

Several organizations miss a vital component of a lean handling system known as PFEP, "A Plan for Every Part." While some companies assume that a lean transformation in their operations should focus on labor, PFEP focuses more on inventory. The PFEP seeks accurate and regulated inventory reductions for every purchased component to make any company's material handling operation … [Read more...] about Why a Plan for Every Part Is Essential to Lean Transformations

Understanding the context of your process

Context, the first lens of the 6CON process development framework, provides the development team with critical information against which they can readily make informed decisions. Context, by itself, does not eliminate the failure modes we have mentioned, but it is the foundation for the rest of the work to come, reducing the likelihood of the failure modes. The components … [Read more...] about Understanding the context of your process