KaiNexus delves into the significance and methodologies of process improvement in businesses. According to a study by the International Quality and Productivity Center (IQPC), businesses that prioritize process improvement witness a substantial increase in operational efficiency and customer satisfaction. Process improvement methodologies, such as Six Sigma, Lean, and Agile, … [Read more...] about The Ultimate Guide to Process Improvement Methodologies For Increased Productivity

Quality

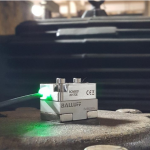

Knowing Your Machine Will Break, and What to Do About it

How many machines do you have on your plant floor past their service life? Often, we specify equipment for a 7- or 10-year usage period but continue to use it long after that has passed. In fact, it isn’t unusual to see operational equipment from the 1970s or earlier! But we are only as strong as our weakest link, and outdated equipment is prone to breakdowns. These unplanned … [Read more...] about Knowing Your Machine Will Break, and What to Do About it

Quality Assurance Checklist: A Quality Management Essential

Quality assurance involves ensuring that all project factors are met and follow expected requirements. This article outlines the differences between quality assurance and quality control as well as best practices. The concept of quality assurance can cover many aspects of various products and services, including design, development, operations, delivery, and more. The … [Read more...] about Quality Assurance Checklist: A Quality Management Essential

The Concept of Quality: Little q VS Big Q.

This article delves into the concept of quality, sketching various aspects of quality that organizations should consider when they relate to their suppliers, who may have different definitions. These aspects include "little quality" and "big quality." For example, little quality (or 'little q') involves whether products that organizations receive are accepted and meet … [Read more...] about The Concept of Quality: Little q VS Big Q.

What if ISO had to explain its changes?

What if ISO had to explain changes to its standards? Should ISO require official documentation explaining the specific value of certain changes to users? This blog post from a quality management expert answers this and similar questions. The author posits whether ISO should require public reasons to the full clauses of its standards and whether ISO should go further in … [Read more...] about What if ISO had to explain its changes?

A conceptual framework of quality cost chain in strategic cost management

This study outlines a method employing the concept of quality cost in Strategic Cost Management (SCM). The authors use appraisal, failure, and preventive (AFP) actions to implement SCM as part of their initial analysis of the organizations' internal value chains. The study goes on to relate AFP actions and costs of quality to identify the study's scope. Researchers … [Read more...] about A conceptual framework of quality cost chain in strategic cost management

Risk-Based Thinking and the IATF 16949 Requirements Related to Risk

Risk-based thinking is one of the more significant additions to ISO 9001:2015's list of quality management principles. Risk-based thinking involves incorporating risk analysis in an organizational quality management system, including certain risks' opportunities, probability, and consequences. The goal is to prevent identifiable problems before they happen, evaluating risks … [Read more...] about Risk-Based Thinking and the IATF 16949 Requirements Related to Risk

Six Sigma in Manufacturing | Advantages & Disadvantages

A strategy that reduces errors and defects in manufacturing is called Six Sigma. Organizations use Six Sigma to increase the quality of their products. Innovations in technology have changed the manufacturing industry. Understanding and adapting to these changes allow Six Sigma to advance towards quality improvement. Lean manufacturing works simultaneously with Six Sigma to … [Read more...] about Six Sigma in Manufacturing | Advantages & Disadvantages

Why Time Study Analysis is Key and How to Conduct One

Organizations can achieve greater efficiency on their production floor through a time study, which observes, records, and evaluates labor work to ensure that qualified employees do specific tasks under specific conditions and at a precise rate. Performing a time study demands attentive preparation and comprehensive planning. This article shows why organizations should consider … [Read more...] about Why Time Study Analysis is Key and How to Conduct One

Workflow Documentation: How to Increase Efficiency, Reduce Error, & Focus On Impactful Tasks

Workflow documentation is more accessible than ever. Rather than having organizations drown in stacks of paper, workflow management software helps companies edit, locate, and store crucial workflow documents. Various workflow management software programs can help automate time-consuming data entry, leaving employees more time to focus on critical business tasks. Further, an … [Read more...] about Workflow Documentation: How to Increase Efficiency, Reduce Error, & Focus On Impactful Tasks

Don’t Follow a Broken Compass: How to Validate Your Data

Lucid's Strategy & Analytics team is responsible for aiding stakeholders in achieving business impact. To do so, they use strategic analyses (recommendations based on data) and data modeling (organizing data to be accessible and useful for the company). Charles Babbage, otherwise known as the “father of the computer” said that “errors using inadequate data are much less … [Read more...] about Don’t Follow a Broken Compass: How to Validate Your Data

Why won’t you leave the process alone? Exploring emotional, motivational and cognitive mechanisms triggering tampering

Although quality professionals aim to improve their products by solving problems, sometimes actions can result in inferior outcomes, a process known as tampering. This paper highlights and analyzes the various mental and behavioral activities that lead quality professionals to tamper as they try to solve problems. Examples include fear of inaction and using past experiences to … [Read more...] about Why won’t you leave the process alone? Exploring emotional, motivational and cognitive mechanisms triggering tampering

A 3-Step Method for Writing LPA Questions

To reduce defects, complaints from customers, and eliminate cost, manufacturers use easy and cost-effective LPAs, or layered process audits. However, to achieve and support plant floor inspections on a regular basis, plants have to overcome their trouble creating LPA questions. What results from a lack of quality LPA questions is people zooming through paperwork with the goal … [Read more...] about A 3-Step Method for Writing LPA Questions

ISO 9001:2015 Certification and Lean Six Sigma

ISO 9001 or Six Sigma? What certification should companies adopt to improve their quality management system? ISO 9001 can help organizations achieve a quality management system to cover their departments, suppliers, and employees. Six Sigma presents a series of mechanisms and methods to streamline business operations and curtail organization-wide waste. Although both … [Read more...] about ISO 9001:2015 Certification and Lean Six Sigma

Why EV Suppliers and Startups Should Implement Layered Process Audits

While the electric vehicle (EV) industry makes momentous gains in wealth, and is expected to quadruple in revenue by 2030, their suppliers typically come from an entrepreneurship or design background.This is where the problem stems from—the best technology does not imply it can be introduced to customers with the best quality. To succeed in the world’s competitive market, there … [Read more...] about Why EV Suppliers and Startups Should Implement Layered Process Audits

Why a Plan for Every Part Is Essential to Lean Transformations

Several organizations miss a vital component of a lean handling system known as PFEP, "A Plan for Every Part." While some companies assume that a lean transformation in their operations should focus on labor, PFEP focuses more on inventory. The PFEP seeks accurate and regulated inventory reductions for every purchased component to make any company's material handling operation … [Read more...] about Why a Plan for Every Part Is Essential to Lean Transformations

How Do Remote Audits and ISO Certification Work?

Nowadays, ISO certification and auditing are essential for organizations to use. Auditing allows for formal accreditation and together, implementing them is the best practice to achieve approval.Remote auditing is now critical with the digital revolution expanding into multiple industrial sectors. Day by day, the significance of remote audits grows as they help manage … [Read more...] about How Do Remote Audits and ISO Certification Work?

5 Worst Consequences Of Poor Customer Service And How To Avoid Them

Devastating effects in business can be caused by inadequate customer service. Customers may choose competitors, resulting in revenue drops and increased costs. In this article, the top five consequences of poor customer service will be discussed with examples on how to negate them. When customers are treated poorly, they may defect to the competition. This causes … [Read more...] about 5 Worst Consequences Of Poor Customer Service And How To Avoid Them

ISO to Develop Design Specification for New Version of ISO 9001

The ISO technical committee, who develops, manages, and updates ISO 9000, is now developing a similar set of design standards for a potential future revision of ISO 9001. TG5 has been assigned to develop these design standards by the ISO/TC 176/SC2 Strategic Planning and Operations Task Group (SPOTG). In April, SPOTG met to review a report from ISO/TC 176/SC2/TG 5 where … [Read more...] about ISO to Develop Design Specification for New Version of ISO 9001

Research Reveals Employee Engagement is Key to Both EHS and ESG Performance

In the health and safety of occupations, employees are faced with the culture and engagement dilemmas of the workplace. According to Technologies LLC’s research, environment, social, and corporate governance performance (ESG) are likely to be majorly impacted. The research report identified that bolstering EGS and EHS performances slows EGS progress when employees are … [Read more...] about Research Reveals Employee Engagement is Key to Both EHS and ESG Performance