This article by Lyssa Cluster provides a comprehensive overview of Agile retrospectives, an essential component of Agile project management. This practice involves regular, structured meetings at the end of each project iteration, allowing teams to reflect on their performance and identify areas for improvement. Cluster offers insights and practical advice for new and … [Read more...] about What is an Agile Retrospective? An Ultimate Guide

Quality

The Gartner Market Guide for Supplier Risk Management Solutions

Gartner's "Market Guide for Supplier Risk Management Solutions" highlights the pressing need for procurement technology leaders to address ongoing supply chain disruptions. Key concerns include supplier viability, cybercrime, and increasing ESG (Environmental, Social, and Governance) regulations. The guide emphasizes the importance of technology in monitoring, managing, and … [Read more...] about The Gartner Market Guide for Supplier Risk Management Solutions

Quality Metrics and Their Reporting

This fairly practical article emphasizes the significance of quality metrics in organizations, offering a methodology for effectively selecting, tracking, and reporting these metrics. The article outlines that quality metrics should be monitored to benefit the enterprise. Good metrics are described as providing an unbiased performance assessment and maintaining a balance … [Read more...] about Quality Metrics and Their Reporting

Quality 4.0: Learning Quality Control, The Evolution of Statistical Quality Control

This article introduces a new concept called Learning Quality Control (LQC), an evolution of Statistical Quality Control (SQC). LQC is a process monitoring system that leverages machine learning and deep learning to enhance quality control in manufacturing. It focuses on real-time defect prediction or detection using historical samples, which include process measurements and … [Read more...] about Quality 4.0: Learning Quality Control, The Evolution of Statistical Quality Control

Evaluating And Validating A Supplier’s Quality The Right Way

This article discusses the importance and methods of assessing a supplier's quality in manufacturing and production processes. The article emphasizes that a supplier's quality directly affects the final product's quality. It categorizes supplier quality into two key aspects: their operational behavior and support towards customers and their ability to provide the best quality … [Read more...] about Evaluating And Validating A Supplier’s Quality The Right Way

ISO 9001 Clause 7.5.3 Control of Documented Information, Explained

Clause 7.5.3 of ISO 9001, titled "Control of Documented Information," is critical to implementing and maintaining a quality management system (QMS) compliant with ISO 9001:2015 standards. This clause necessitates the organization to systematically organize and collect essential information pertinent to various processes and develop simplified, user-friendly materials suitable … [Read more...] about ISO 9001 Clause 7.5.3 Control of Documented Information, Explained

Coordinating Quality Decisions in a Two-Stage Supply Chain under Buyer Dominance

This academic article investigates quality decision-making in a two-stage supply chain under buyer dominance. The research delves into the complexities of quality control in supply chains, noting that increased screening efforts can considerably affect consumer satisfaction by reducing product returns and boosting demand. However, one key issue is that one actor in the supply … [Read more...] about Coordinating Quality Decisions in a Two-Stage Supply Chain under Buyer Dominance

A Benefit Costing Process for Lean Six Sigma Programs

This academic study published in "The TQM Journal," addresses the gap between financial measurement and Lean Six Sigma (LSS) methodologies in process improvement initiatives. The study aims to enhance employee engagement by designing a process and a benefit measuring methodology that aligns with financial metrics and LSS principles, particularly in eliminating waste. The … [Read more...] about A Benefit Costing Process for Lean Six Sigma Programs

ASQ Releases 2023 Insights On Excellence Category Report

(Must enter contact information to receive full PDF report) The 2023 "ASQE Insights On Excellence Category Report" analyzes the trends and shifts in quality management practices across various industries. The quality report, based on data collected via a survey in 2022, builds upon foundational data established since 2020 and introduces a new category focused on … [Read more...] about ASQ Releases 2023 Insights On Excellence Category Report

What Quality Management Trends to Watch For in 2024

The evolving landscape of quality management emphasizes the integration of new technologies and methodologies to enhance efficiency, reduce risks, and promote operational excellence. The article points out several critical trends expected to impact the quality management field significantly by 2024, such as machine learning. One major trend is augmented analytics, which … [Read more...] about What Quality Management Trends to Watch For in 2024

“Does ISO 9001 really require THAT?”

A common issue faced by professionals working with the ISO 9001 standard involves dealing with individuals who misinterpret the standard's requirements in extreme ways. The article describes scenarios where people, sometimes even auditors, assert that ISO 9001 requires absurd or overly specific practices, such as documenting paper clip usage or placing clear labels on items. … [Read more...] about “Does ISO 9001 really require THAT?”

Management Reviews Under ISO 9001: How Frequently Should They Be Held?

This forum thread delves into setting intervals for Management Reviews as per ISO 9001:2015. The discussion was initiated by a user who faced an audit issue due to not holding Management Review Meetings (MRM) quarterly, as stated in their procedures manual. The user expressed the challenges of having these meetings due to time constraints and sought advice on whether it's … [Read more...] about Management Reviews Under ISO 9001: How Frequently Should They Be Held?

Is there an obligation to accept customer-led audits?

In quality management, audits are a cornerstone, ensuring that processes and products adhere to specified requirements. The discussion on customer audits in the automobile industry, as explored in this Elsmar Cove forum thread, offers a lens into the broader intricacies of quality assurance in real-world business contexts. The forum thread delves into customer audits in the … [Read more...] about Is there an obligation to accept customer-led audits?

The Role of Lean Six Sigma in Driving Sustainable Manufacturing Practices

The article from Frontiers analyzes the intricate relationship between Lean Six Sigma (LSS) methodology and its influence on sustainable manufacturing practices. Amidst the backdrop of an increasingly competitive manufacturing landscape, the study highlights the growing inclination of companies towards innovative methodologies like LSS to bolster their operational efficiency, … [Read more...] about The Role of Lean Six Sigma in Driving Sustainable Manufacturing Practices

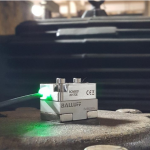

Unleashing The Potential: Quality Validation In Additive Manufacturing

This article from Metrology News looks into the significance of quality validation in additive manufacturing (AM). As AM, commonly known as 3D printing, continues to gain traction across various industries, ensuring the quality and reliability of printed components becomes paramount. AM's unique layer-by-layer construction method introduces potential inconsistencies and defects … [Read more...] about Unleashing The Potential: Quality Validation In Additive Manufacturing

Risk-Based Thinking: An Essential Part of ISO 9001

The article delves into the significance of risk-based thinking in the ISO 9001:2015 Quality Management System (QMS) standard. One of the primary concepts introduced in this standard is the systematic approach to considering and addressing risks and opportunities as an essential component of the quality management system. This approach contrasts with the previous version, ISO … [Read more...] about Risk-Based Thinking: An Essential Part of ISO 9001

The Ultimate Guide to Process Improvement Methodologies For Increased Productivity

KaiNexus delves into the significance and methodologies of process improvement in businesses. According to a study by the International Quality and Productivity Center (IQPC), businesses that prioritize process improvement witness a substantial increase in operational efficiency and customer satisfaction. Process improvement methodologies, such as Six Sigma, Lean, and Agile, … [Read more...] about The Ultimate Guide to Process Improvement Methodologies For Increased Productivity

Knowing Your Machine Will Break, and What to Do About it

How many machines do you have on your plant floor past their service life? Often, we specify equipment for a 7- or 10-year usage period but continue to use it long after that has passed. In fact, it isn’t unusual to see operational equipment from the 1970s or earlier! But we are only as strong as our weakest link, and outdated equipment is prone to breakdowns. These unplanned … [Read more...] about Knowing Your Machine Will Break, and What to Do About it

Quality Assurance Checklist: A Quality Management Essential

Quality assurance involves ensuring that all project factors are met and follow expected requirements. This article outlines the differences between quality assurance and quality control as well as best practices. The concept of quality assurance can cover many aspects of various products and services, including design, development, operations, delivery, and more. The … [Read more...] about Quality Assurance Checklist: A Quality Management Essential

The Concept of Quality: Little q VS Big Q.

This article delves into the concept of quality, sketching various aspects of quality that organizations should consider when they relate to their suppliers, who may have different definitions. These aspects include "little quality" and "big quality." For example, little quality (or 'little q') involves whether products that organizations receive are accepted and meet … [Read more...] about The Concept of Quality: Little q VS Big Q.