- Traceability in manufacturing refers to the capability to track and document every aspect of the production process, from raw material procurement to the finished product reaching the consumer.

- The implementation of traceability systems involves the utilization of unique identifiers such as barcodes, QR codes, or RFID tags that facilitate the tracking of products throughout the production cycle and supply chain.

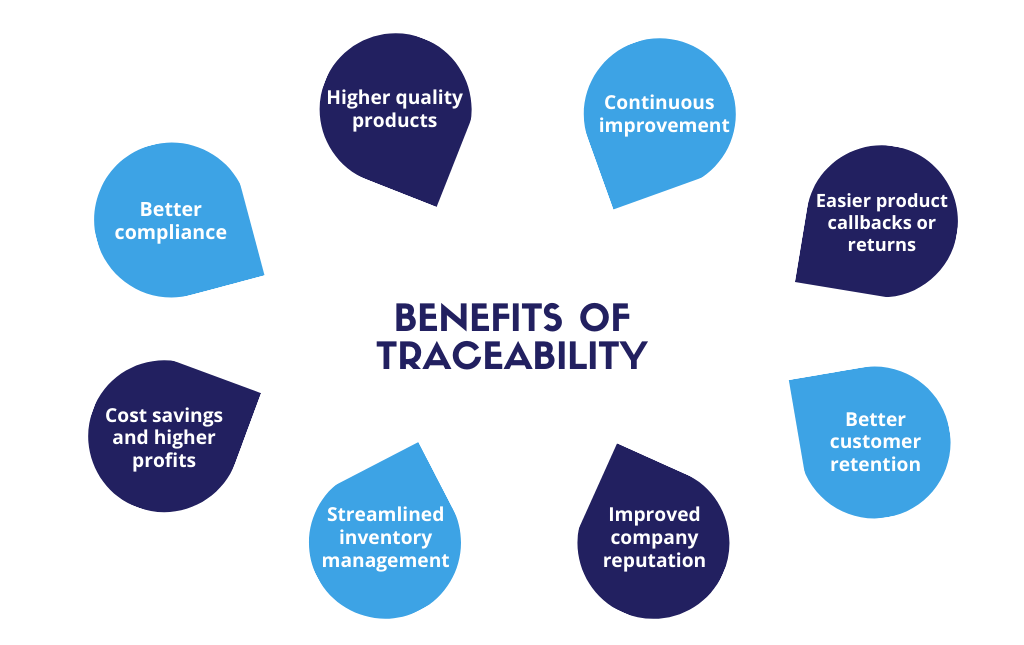

- The benefits of implementing traceability are manifold. It allows businesses to optimize production, reduce waste, manage recalls more efficiently, and ensure compliance with international standards like ISO 9001:2015.

Traceability in manufacturing refers to the capability to track and document every aspect of the production process, from raw material procurement to the finished product reaching the consumer. This ability is becoming increasingly crucial in various sectors due to the stringent regulations that require detailed tracking to ensure compliance and quality control. Traceability helps manufacturers maintain quality standards but also assists in pinpointing inefficiencies, managing product recalls effectively, and enhancing customer satisfaction by providing the reliability and safety of products.

The implementation of traceability systems involves the utilization of unique identifiers such as barcodes, QR codes, or RFID tags that facilitate the tracking of products throughout the production cycle and supply chain. These systems record detailed information at each stage of the process, allowing manufacturers to quickly trace the origin of components, identify any errors, and understand the flow of materials and products through their processes. This comprehensive tracking is essential for conducting root cause analyses, preventing potential faults before they escalate into larger issues, and maintaining a history of manufacturing data that is crucial for meeting regulatory demands.

The benefits of implementing traceability are manifold. It allows businesses to optimize production, reduce waste, manage recalls more efficiently, and ensure compliance with international standards like ISO 9001:2015. Moreover, traceability enhances customer trust by providing transparency and accountability in the manufacturing process. As industries increasingly move towards global supply chains and more complex production models, the role of traceability in ensuring quality and safety cannot be overstated. Thus, investing in robust traceability systems is a regulatory necessity and a strategic advantage that can lead to better business outcomes.

Leave a Reply

You must be logged in to post a comment.