The Cost of Quality (CoQ) represents the total investment a company makes to ensure products meet quality standards and the expenses incurred when quality failures occur. CoQ is divided into two primary categories: the cost of conformance, which includes prevention and appraisal costs, and the cost of non-conformance, which covers internal and external failure costs. Businesses … [Read more...] about Cost of Quality: Cost of Conformance & Cost of Nonconformance

Quality-Cost of Quality

Cost of Quality: The Hidden Truth About Your Ultimate Quality Metric

Cost of Quality (CoQ) is a critical metric in manufacturing, often accounting for 15-40% of revenue. This includes the Cost of Poor Quality (CoPQ) related to failures and the Cost of Good Quality (CoGQ) associated with prevention and appraisal. Many manufacturers focus on visible metrics like scrap and rework, overlooking the extensive hidden costs of failures, such as recalls, … [Read more...] about Cost of Quality: The Hidden Truth About Your Ultimate Quality Metric

Enhancing Product Quality: Lessons from Implementing CAPA and NPDI in QMS

This case history describes a journey to improving product quality through a Quality Management System (QMS) which began with a proactive approach to persistent quality challenges. Initially, a reactive response led to recurring issues that eroded customer confidence. This experience highlighted the need for a structured approach, integrating CAPA (Corrective and Preventive … [Read more...] about Enhancing Product Quality: Lessons from Implementing CAPA and NPDI in QMS

Defining Quality Standards: A Guide for Product Development Prototypes

This article from a China-focused contract manufacturing sourcing company describes prototyping as a crucial step in product development. They describe their experience in prototyping as It transforms concepts into tangible models that allow teams to explore design elements, functionality, and user experience. Prototypes are invaluable for identifying design flaws or functional … [Read more...] about Defining Quality Standards: A Guide for Product Development Prototypes

Cost of Quality: The Hidden Truth About Your Ultimate Quality Metric

Manufacturers across various industries, from aerospace to medical devices, face immense pressure to ensure product quality and avoid costly defects. The average cost of a significant product recall can reach $12 million, possibly even larger sums when factoring in reputational damage. Despite these risks, many manufacturers miscalculate their total cost of quality (TCoQ), … [Read more...] about Cost of Quality: The Hidden Truth About Your Ultimate Quality Metric

Think about your product before you build it

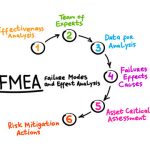

Implementing Failure Mode and Effects Analysis (FMEA) during the design process can save products before they fail. FMEA involves thinking through all the possible ways a product might fail before it goes into production and then updating the design to address those potential failures. By systematically identifying and prioritizing these failures using a Risk Priority Number … [Read more...] about Think about your product before you build it

How Scrap and Rework Affect Cost of Quality and OEE

Tracking quality metrics is crucial for continuous improvement, and understanding their interplay can help identify key leverage points for maximum impact. This article explores the relationship between scrap, rework, cost of quality, and Overall Equipment Effectiveness (OEE). OEE is a composite metric that measures availability, performance, and quality, where each element is … [Read more...] about How Scrap and Rework Affect Cost of Quality and OEE

Book Review: FMEA Essentials: A Handbook for Beginners and Practitioners

"FMEA Essentials: A Handbook for Beginners and Practitioners" by Stephen Cole is a comprehensive and accessible guide that demystifies the complexities of Failure Mode and Effects Analysis (FMEA). Whether you are new to FMEA or a seasoned practitioner, this handbook provides a step-by-step approach to effectively understanding and implementing the FMEA process. Cole’s extensive … [Read more...] about Book Review: FMEA Essentials: A Handbook for Beginners and Practitioners

What is COPQ (Cost of Poor Quality)?

The Cost of Poor Quality (COPQ) encapsulates the financial costs of failing to meet production and service delivery standards. These costs are broadly categorized into four types: prevention costs, appraisal costs, internal failure costs, and external failure costs. Prevention costs involve expenditures to prevent defects from occurring, such as training and quality planning. … [Read more...] about What is COPQ (Cost of Poor Quality)?

Results for the 23rd Annual Quality Spending Survey

Quality Magazine's 23rd Annual Spending Study, conducted by Clear Seas Research, found that companies are spending more on artificial intelligence (AI) and automation. According to the survey, there is a notable increase in spending on AI, with 55% of companies planning to raise their investment in 2024. Additionally, 46% of companies currently use automation, while 8% use AI. … [Read more...] about Results for the 23rd Annual Quality Spending Survey

A conceptual framework of quality cost chain in strategic cost management

This study outlines a method employing the concept of quality cost in Strategic Cost Management (SCM). The authors use appraisal, failure, and preventive (AFP) actions to implement SCM as part of their initial analysis of the organizations' internal value chains. The study goes on to relate AFP actions and costs of quality to identify the study's scope. Researchers … [Read more...] about A conceptual framework of quality cost chain in strategic cost management

Are Supply Chains Too Lean?

Supply chains everywhere have become too lean — and not just in auto. This trend was highlighted by pandemic-driven shortages in virtually everything – drugs, medical equipment, construction supplies, even toilet paper. The chip shortage alone is projected to impact global automotive sales by 1.3 million units in 2022. The issues behind these shortages show no signs of … [Read more...] about Are Supply Chains Too Lean?

Improving Quality, Decreasing Costs

Digital transformation initiatives that aim at getting manufacturers to Industry 4.0 have been around a while and will assuredly continue to be with us for quite a while longer. But what can often get lost by manufacturers in the push to digital transformation are the reasons why one would want to undertake this journey in the first place, which in turn should all boil down to … [Read more...] about Improving Quality, Decreasing Costs

Spending is Back: The 21st Annual Quality Spending Survey

It’s time to invest. According to our 21st Annual Quality Spending Survey, respondents are interested in purchasing new equipment, software and services now. Last year at this time, respondents were worried about family members contracting COVID-19 as well as about the current economy. Those fears have declined this year. While respondents plan to invest similar … [Read more...] about Spending is Back: The 21st Annual Quality Spending Survey