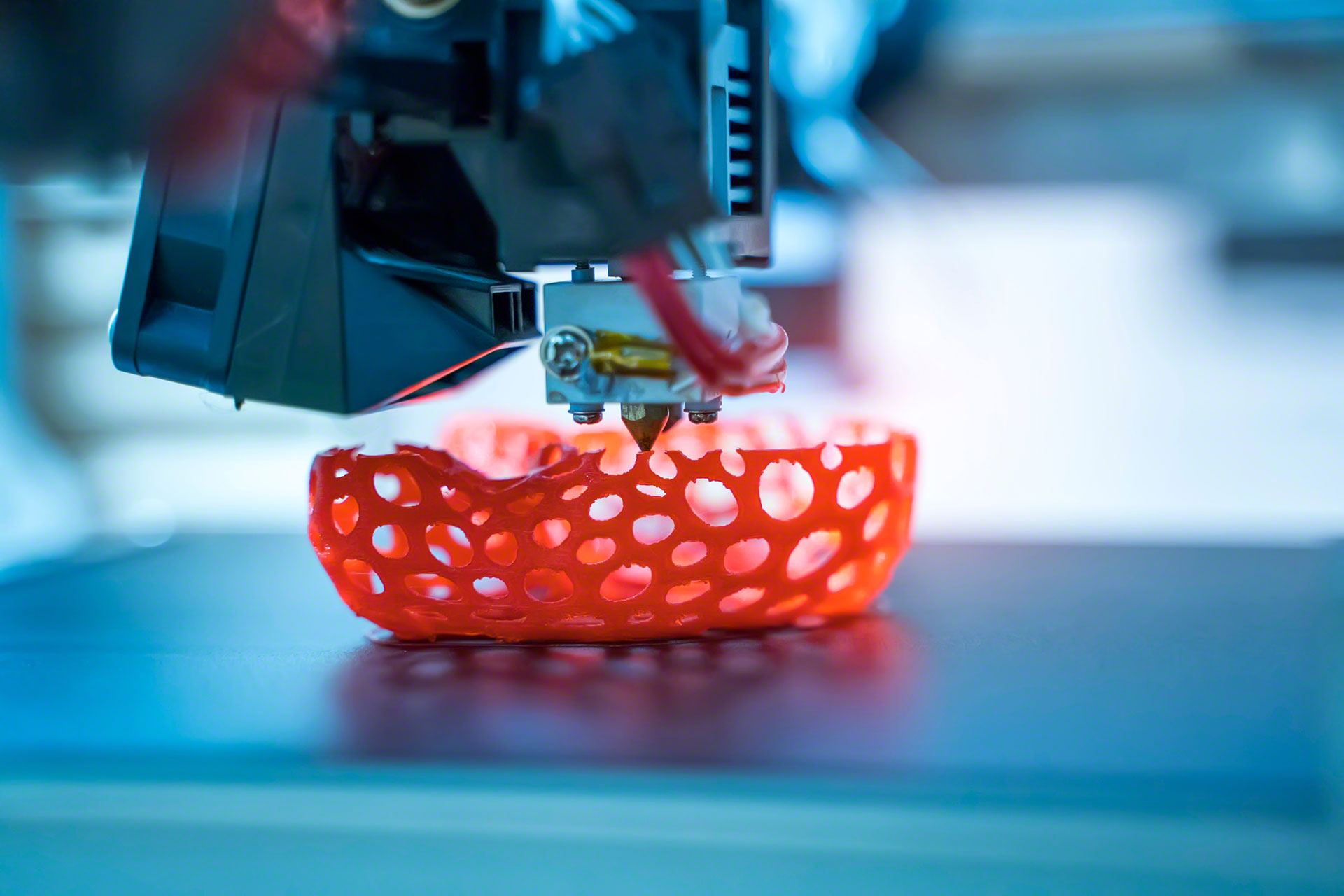

- 3D printing, also known as additive manufacturing, has been hailed by technology watchers as a revolutionary technique for several decades.

- Some organizations have succeeded; others continually see disappointment as 3D printing falls short of some expectations.

- The authors use a model to demonstrate how 3D printing has made a more lasting impact in some business and societal areas while not in others.

This study looks into operations and supply chain management, given advances in 3D printing. 3D printing, also known as additive manufacturing, has been hailed as a revolutionary technology for several decades, with the potential to disrupt traditional manufacturing and supply chain processes.

As 3D printing use has grown, organizations have seen greater success, while others continually see disappointment as 3D printing falls short of more improbable expectations. This special study aims to give observational evidence and add to the conceptual understanding of 3D printing to estimate better the potential impacts of additive manufacturing on businesses and society.

The study’s authors use a model to demonstrate how 3D printing has made a more lasting impact in some business and societal areas while not in others. The authors argue that three factors (operational, contextual, and strategic) may affect an organization’s use of 3D printing more than other variables, particularly if the organization wants to reap the positives of additive manufacturing.

Leave a Reply

You must be logged in to post a comment.