- FMEA is widely used in automotive and manufacturing industries to identify and prevent potential failures.

- The traditional RPN method has limitations, prompting the development of improved models.

- There is a gap in the application of FMEA in the service sector.

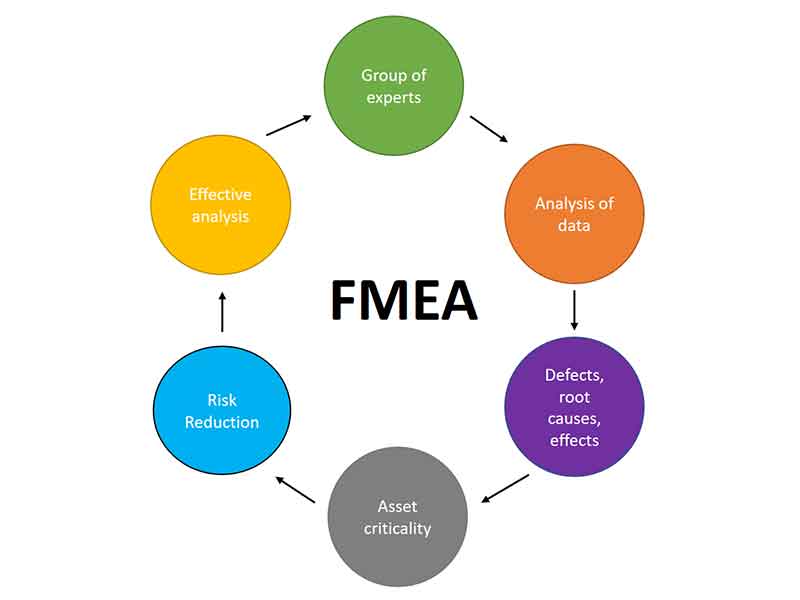

Failure mode and effects analysis (FMEA) is a risk assessment tool developed in the 1960s by the aerospace industry. It is intended to identify and prevent potential failures in systems, processes, designs, or services before they reach the customer. It is extensively applied across various sectors, including automotive, aerospace, nuclear, and electronics. The primary objective of FMEA is to enhance system performance by identifying failure modes, evaluating their causes and effects, and planning corrective actions during the design and production stages.

The conventional risk priority number (RPN) method used in FMEA has been criticized for its limitations, leading to the development of various improved risk priority models. The RPN is calculated by multiplying a failure mode’s occurrence, severity, and detection. This structured technique helps prioritize failure modes, ensuring resources are allocated to the most severe risks. Despite its widespread use, the service sector has seen limited application of FMEA.

A systematic review of 50 FMEA-related papers published between 1998 and 2019 reveals that the automotive and manufacturing industries dominate FMEA implementation. These industries utilize FMEA to identify failure modes, assess their impacts, and implement corrective actions to improve quality and reliability. The review categorizes the papers by industry type and output, offering valuable insights for industries looking to implement FMEA, particularly in the goods and services sectors.

Future research is encouraged to expand the scope of this review by incorporating more databases, book chapters, dissertations, and other references. Additionally, it is suggested that the role of FMEA be explored in enhancing six-sigma-oriented service systems and its contribution to creating value within collaborative business frameworks. There is a significant opportunity for further study on FMEA’s application in the service sector, which remains underexplored.

Leave a Reply

You must be logged in to post a comment.