- Quality KPIs like First Pass Yield, Defects Per Unit, and Scrap Rate are essential for improving manufacturing efficiency and reducing waste.

- Metrics such as Cost of Poor Quality and Warranty Claims help highlight financial impacts and drive targeted quality improvements.

- A customizable workflow enables real-time KPI tracking, analysis, and corrective actions, enhancing operational performance.

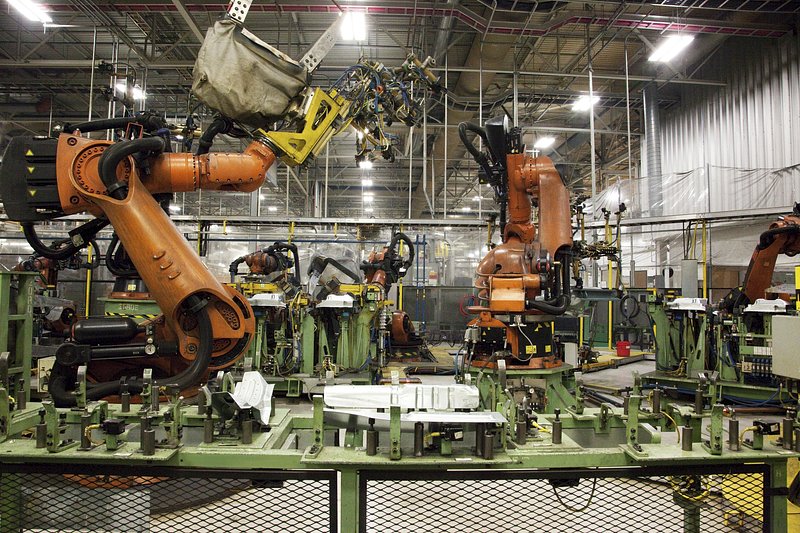

Tracking and optimizing Key Performance Indicators (KPIs) is vital for manufacturing success, ensuring quality and efficiency. Metrics such as First Pass Yield (FPY) gauge production efficiency by measuring the percentage of products completed correctly on the first attempt. Defects Per Unit (DPU) and Scrap Rate monitor product defects and material waste, helping identify inefficiencies and areas for improvement.

Financial KPIs, including Cost of Poor Quality (COPQ) and Warranty Claims, highlight the economic impact of defects and customer dissatisfaction. For instance, a high COPQ could indicate significant rework costs, prompting a review of supplier agreements or production protocols. Monitoring Supplier Quality Index (SQI) ensures high-quality inputs, reducing downstream issues.

Customizable workflows streamline tracking these KPIs, enabling manufacturers to capture data, analyze trends, and implement improvements in real time. By integrating these metrics into daily operations, manufacturers can achieve operational excellence, enhance customer satisfaction, and foster continuous improvement.

Leave a Reply

You must be logged in to post a comment.