- Generative AI (genAI) revolutionizes defect detection and root cause analysis (RCA) by offering real-time monitoring, learning adaptability, and contextual understanding for enhanced quality control in manufacturing.

- GenAI’s capabilities surpass vision AI by analyzing data streams, identifying emerging defect patterns, and integrating natural language processing for intuitive system interaction.

- Companies like BMW and Citic Pacific Special Steel demonstrate significant efficiency improvements, cost savings, and defect reduction through genAI-powered RCA systems.

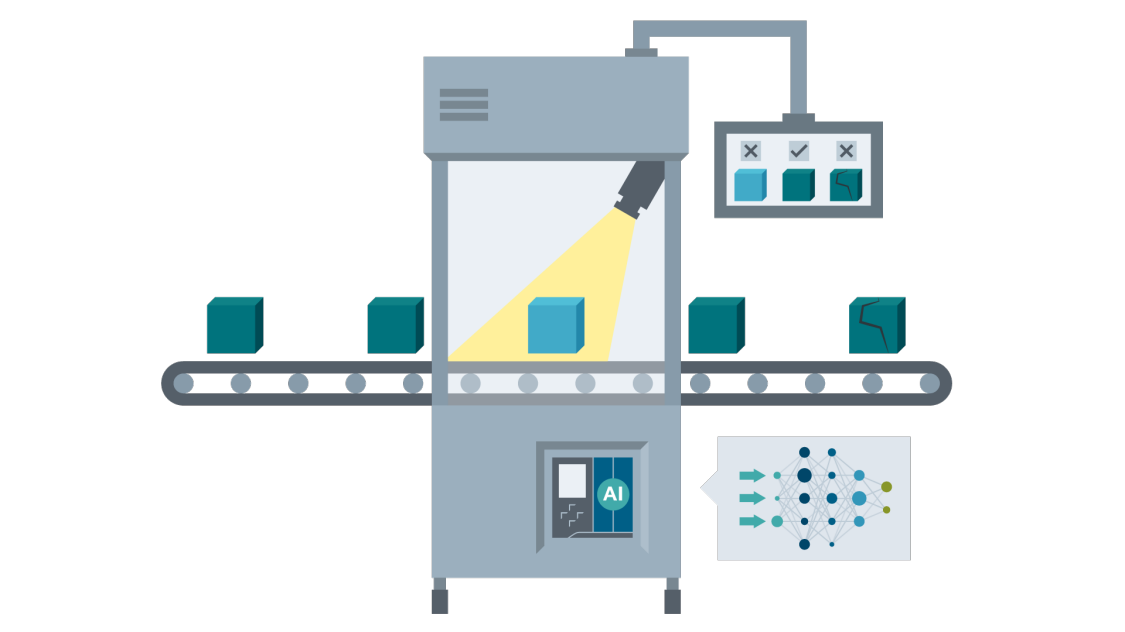

Generative AI transforms quality control in manufacturing by enabling continuous defect detection and RCA. Unlike traditional vision AI, which excels in visual anomaly detection, genAI leverages advanced learning, contextual understanding, and data analysis to predict and prevent defects. By analyzing diverse data streams and adapting to changing conditions, genAI can identify novel defect patterns and their root causes, facilitating more efficient and reliable production processes.

GenAI’s applications span various sectors, such as steel manufacturing and automotive production, driving significant cost savings and operational improvements. For example, BMW integrated genAI into its assembly line via a digital twin, reducing alignment-related defects by 30% and enhancing production efficiency. Similarly, Citic Pacific Special Steel increased throughput by 15% and reduced energy consumption by 11% by optimizing blast furnace operations with genAI-based RCA.

Implementing genAI requires robust training datasets, system adaptability, and operator training. Key steps include assessing current processes, identifying genAI applications, integrating the system into existing workflows, and providing continuous updates. Success can be measured through KPIs like defect detection rates, production downtime reduction, cost savings, and customer satisfaction. GenAI is poised to redefine quality control, offering unprecedented opportunities for efficiency and precision in manufacturing.

Leave a Reply

You must be logged in to post a comment.