The 8D (Eight Disciplines) methodology is a systematic problem-solving framework originally developed by Ford to identify and eliminate the root causes of chronic or recurring production and quality issues. Though initially intended for the automotive sector, it is widely used across industries, especially those certified under ISO 9001 or regulated by the FDA. The process … [Read more...] about Mastering the 8D Problem-Solving Methodology: A Guide to Root Cause Analysis in Manufacturing

Quality-Root Cause

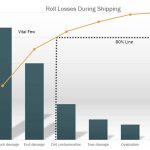

Pareto Chart: How to Use It to Identify Root Causes

Pareto charts are a practical tool for analyzing root causes in business processes, based on the 80/20 principle, which states that 80% of problems often arise from 20% of causes. This makes them particularly effective for prioritizing issues and focusing on the most impactful solutions. Their simplicity and flexibility make them a go-to tool for Lean Six Sigma practices and … [Read more...] about Pareto Chart: How to Use It to Identify Root Causes

Root causes on the back of an envelope

What if a root cause analysis as complex and supercharged like illegal immigration could start with the question: "Is there a problem?" The answer is affirmative for both procedural and other (in this case humanitarian) reasons. Not viewing this type of problem from a political, but rather a procedural standpoint is an example of the this critical quality process potentially … [Read more...] about Root causes on the back of an envelope

12 Strategies for Successful CAPA Management

Successful Corrective and Preventive Action (CAPA) management is critical for companies to maintain compliance, especially during certification audits or customer inspections. A well-managed CAPA system helps avoid compliance issues and plays a pivotal role in continuous improvement, leading to safer, higher-quality products. Poorly managed CAPA processes, however, can result … [Read more...] about 12 Strategies for Successful CAPA Management

Root cause analysis: 5 Whys, Fishbone, and What Else?

In a forum discussion about root cause analysis (RCA), participants shared their experiences and concerns with traditional methods like the 5 Whys and Fishbone diagrams. They note that these tools are often applied inconsistently across industries, sometimes leading to incorrect conclusions or repeated trials to find the root cause. The discussion highlighted that these … [Read more...] about Root cause analysis: 5 Whys, Fishbone, and What Else?

An Introduction to AIAG & VDA FMEA Methodology

The AIAG & VDA Failure Mode & Effects Analysis (FMEA) represents a significant shift in how Failure Modes and Effects Analysis is approached and applied in various industries. Originally rooted in the automotive sector, FMEA methodologies have broadened to include industries like aviation and medical equipment, highlighting its universal relevance. The AIAG & VDA … [Read more...] about An Introduction to AIAG & VDA FMEA Methodology

Podcast: Root Cause Analysis and Its Benefits

Root Cause Analysis (RCA) is a critical tool for identifying an organization's underlying reasons for non-conformance. It emphasizes the importance of looking beyond superficial causes, such as operator error, and delves into systemic issues that lead to problems. This approach advocates for a shift from blaming individuals to examining the processes and systems that may … [Read more...] about Podcast: Root Cause Analysis and Its Benefits

Finding root causes, Part 1: 5-Whys

Last week I talked about what a "real root cause" actually is, but I didn't say much about how to find them. Maybe a couple more words would be helpful. There are several tools you can use to dig out a root cause from under a big pile of symptoms. The simplest one is called a "Five-why analysis," and you can think of it as "problem-solving by a bright, persistent … [Read more...] about Finding root causes, Part 1: 5-Whys