This paper introduces a machine learning-based strategy to improve data cleaning by integrating unstructured textual data with traditional structured datasets. Recognizing that structured data often contains errors due to inconsistencies, omissions, or conflicts, the authors propose leveraging textual descriptions, such as product titles or clinical trial summaries, to predict … [Read more...] about Improving Data Cleaning by Learning From Unstructured Textual Data

Quality-Continuous Improvement

Why Non-Automotive Companies Need Process Audits

VDA 6.3 is a process audit standard designed to assess the quality and stability of manufacturing and supply chain processes. Structured around seven core elements—ranging from supplier evaluation to production, customer service, and continuous process monitoring—it emphasizes risk management and process reliability. Each area is scored to identify non-conformities and … [Read more...] about Why Non-Automotive Companies Need Process Audits

How Embedded Quality guides organizations moving from strictly compliance to delivered quality

Conventional quality management, rooted in audits and regulatory compliance, is no longer sufficient to meet the demands of today’s competitive and volatile business environment. Chief Quality Officers (CQOs), now entering the C-suite, are expected to shift away from reactive, siloed practices and toward strategic leadership. Despite widespread compliance, product recalls have … [Read more...] about How Embedded Quality guides organizations moving from strictly compliance to delivered quality

Total Quality Management Interventions and Benchmarking in the Impact of Organizational Culture and Performance

The study explores the relationship between organizational culture, TQM interventions, and benchmarking in driving business performance, particularly within manufacturing SMEs in Jordan. While previous research has presented conflicting views on whether culture positively impacts performance, this study confirms that a well-defined organizational culture strengthens TQM … [Read more...] about Total Quality Management Interventions and Benchmarking in the Impact of Organizational Culture and Performance

Quality 5.0 – Redefining Excellence In Human-Machine Collaboration Age

Quality 5.0 marks a transformative shift in quality management, redefining excellence through the synergy of human intelligence and machine capabilities. Unlike previous iterations that focused on inspection, process control, or digital enhancements, this new paradigm integrates artificial intelligence, robotics, and data-driven decision-making with human creativity, … [Read more...] about Quality 5.0 – Redefining Excellence In Human-Machine Collaboration Age

A Management System for Data Quality

A Data Quality Management System (DQMS) offers organizations a structured approach to managing data quality, adapting ISO 9001 principles to the data domain. While ISO 27001 is widely recognized for information security, and ISO 8000 focuses on specific aspects of data quality, ISO 9001 provides a general framework that can be effectively applied to ensure high data quality … [Read more...] about A Management System for Data Quality

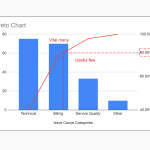

Using Pareto Analysis to Boost Efficiency

Pareto analysis, derived from the 80/20 rule, enables project managers to focus on the 20% of tasks that deliver 80% of the value, enhancing efficiency and productivity. This approach helps teams identify and address the root causes of issues, providing a clear roadmap for prioritizing impactful tasks. By organizing issues into categories, scoring their significance, and … [Read more...] about Using Pareto Analysis to Boost Efficiency

A Single Quality Principle for Value and Balance

The quality profession must evolve to meet modern industry demands by embracing a unifying principle grounded in "value and balance." Value is the ratio of utility produced to resources consumed, highlighting the need to eliminate waste and maximize efficiency. This approach extends beyond traditional quality definitions, like fitness for use or conformance to requirements, … [Read more...] about A Single Quality Principle for Value and Balance

Critical Aspects of Quality Management Systems: Focusing on the Validation Process

In regulated industries such as pharmaceuticals, medical devices, and food manufacturing, validation of Quality Management Systems (QMS) ensures compliance with standards like FDA 21 CFR Part 11, ISO 13485, and EU MDR. (These tools, while not required in less regulated industries, are valuable for maintaining product/service integrity and can be used as models there.) … [Read more...] about Critical Aspects of Quality Management Systems: Focusing on the Validation Process

Data Speaks for Itself: Data Validation – Data Accuracy Imposter or Assistant?

Data validation and accuracy are often conflated in data quality management but serve different purposes. Validation identifies incorrect values through rule-based tests, while accuracy requires comparing data to authoritative sources. Validation alone cannot guarantee accuracy, as it may overlook errors in seemingly valid records. Achieving true accuracy demands … [Read more...] about Data Speaks for Itself: Data Validation – Data Accuracy Imposter or Assistant?

Exploratory image data analysis for quality improvement

Exploratory Image Data Analysis (EIDA) builds on the principles of exploratory data analysis (EDA) by adapting its framework for image data, allowing for hypothesis generation and quality improvement. The EIDA framework involves four key steps: image processing to enhance and prepare images for analysis, quantitative data analysis to derive actionable insights, identification … [Read more...] about Exploratory image data analysis for quality improvement

Book Review: The Long Journey to Lean Management

A new book emphasizes that: Reviewer Jim Womack explores the evolution of lean management, emphasizing the necessity of a cohesive management system to build sustainable lean enterprises. He reflects on earlier approaches, such as Pascal Dennis’s "Getting the Right Things Done," which focused on strategic alignment through hoshin deployment, and Jim Lancaster’s "The Work … [Read more...] about Book Review: The Long Journey to Lean Management

Insights into quality professionals’ adoption of Quality 4.0 in the high-tech industry

This study investigates factors impacting the adoption of Quality 4.0 technologies by quality professionals in high-tech industries using the Technology Acceptance Model (TAM). The findings highlight that perceived ease of use significantly influences professionals’ attitudes and behavioral intentions toward these technologies, emphasizing the need for confidence-building … [Read more...] about Insights into quality professionals’ adoption of Quality 4.0 in the high-tech industry

Quality Assurance in Manufacturing: An In-Depth Guide to Achieve Customer Confidence

In manufacturing, quality assurance (QA) is essential for building customer trust and maintaining competitive advantage. Companies aim to meet and exceed quality standards by implementing structured QA processes, ensuring each product consistently satisfies customer expectations. The stakes are high—product recalls, costly liability claims, and reputational damage can arise … [Read more...] about Quality Assurance in Manufacturing: An In-Depth Guide to Achieve Customer Confidence

Essential Quality Tools for Effective Process Improvement

Quality tools play a critical role in process improvement and product quality assurance. Organizations can effectively monitor, analyze, and improve their processes by utilizing these tools. Examples include Acceptance Sampling Plans, which allow for batch evaluation without inspecting every item, and Control Charts that help track process stability over time. Other tools, … [Read more...] about Essential Quality Tools for Effective Process Improvement

Using 7 QC Tools For Quality Improvement and Customer Satisfaction

The 7 QC tools, developed by Kaoru Ishikawa, are essential for quality improvement and customer satisfaction across industries. These tools—histogram, Pareto Chart, Cause and Effect Diagram, Flowchart, Scatter Diagram, Control Chart, and Check Sheet—allow organizations to systematically analyze and resolve quality issues. Each tool helps businesses visually represent data, … [Read more...] about Using 7 QC Tools For Quality Improvement and Customer Satisfaction

Continuous Improvement vs. Operational Excellence: Streamlining Business Operations

While related, continuous improvement and operational excellence serve different but complementary roles in business operations management. Continuous improvement is incremental enhancements to existing processes to reduce waste, improve quality, and optimize human potential. It involves a systematic approach that includes customer focus, leadership engagement, employee … [Read more...] about Continuous Improvement vs. Operational Excellence: Streamlining Business Operations

Process intelligence in the continuous improvement cycle: A comprehensive approach

In today’s rapidly evolving business environment, staying competitive requires companies to be agile and adaptable. Process intelligence plays a crucial role by providing a software-based methodology that helps organizations thoroughly understand and analyze their internal processes. This capability allows businesses to collect, visualize, and assess real-time operational data, … [Read more...] about Process intelligence in the continuous improvement cycle: A comprehensive approach

Founder of Toyota Production System Taiichi Ohno’s “Improvement Spirit”

The book The Origin of Toyota’s Strength: Taiichi Ohno’s Improvement Spirit offers a deep exploration of the ideas and methods of Taiichi Ohno, the creator of the Toyota Production System (TPS). Through memorials, lectures, and interviews, the book highlights Ohno's unique management approach, which is characterized by a relentless focus on eliminating waste and fostering a … [Read more...] about Founder of Toyota Production System Taiichi Ohno’s “Improvement Spirit”

Measurement Uncertainty 101: Automation, Bias, and Advanced Management

Automation in manufacturing relies heavily on precise and accurate data, making the management of measurement uncertainty crucial. As processes become more automated and involve less human intervention, metrologists must carefully monitor uncertainties throughout the production cycle. Even small errors can accumulate over time, leading to significant issues in the final … [Read more...] about Measurement Uncertainty 101: Automation, Bias, and Advanced Management