- Failure Mode and Effects Analysis (FMEA) is a crucial tool for identifying and mitigating risks in product design, process design, root cause analysis, corrective action, and complaint management.

- FMEAs should be integrated into a flexible quality management system (QMS) to ensure continuous monitoring, updating, and application across the quality chain.

- Real-world data, such as customer complaints and corrective actions, play a vital role in refining FMEA assessments and improving risk mitigation strategies.

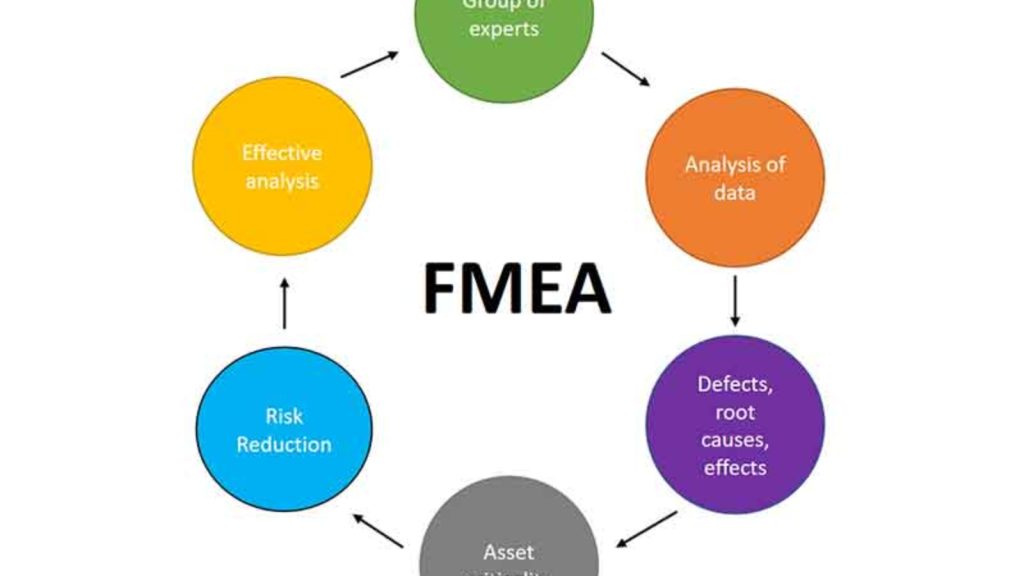

Failure Mode and Effects Analysis (FMEA) is a structured methodology widely used in industries like manufacturing, pharmaceuticals, and aerospace to identify potential failure points in products or processes and implement preventive measures. Its seven-step process includes defining potential failures, calculating risk priority numbers (RPN), and implementing controls to mitigate risks. FMEAs are essential during product design (DFMEA) and process design (PFMEA) stages, allowing companies to address risks such as component failures, assembly issues, or environmental factors early in development.

Beyond the design phase, FMEAs also play a critical role in root cause analysis, corrective action, and complaint management. By revisiting and updating FMEAs based on real-world data, manufacturers can uncover hidden risks, validate the effectiveness of corrective actions, and prevent the recurrence of failures. For instance, customer complaints can reveal unexpected failure modes, necessitate reevaluation of risk rankings, and highlight gaps in detection methods.

A robust quality management system (QMS) with integrated FMEA tools is essential for maximizing the effectiveness of this methodology. Automated systems enable seamless linking of FMEAs to processes like corrective actions, complaint workflows, and root cause analysis. Centralized dashboards and reporting further ensure that FMEAs remain dynamic documents, continuously updated to reflect the current risk landscape. This integrated approach fosters a proactive risk management culture, enhancing overall quality and operational resilience.

Leave a Reply

You must be logged in to post a comment.