- Gage R&R (Gage Repeatability and Reproducibility) is not a requirement for calibrations under ISO 9001, but it can help ensure measurement system accuracy and repeatability for specific applications.

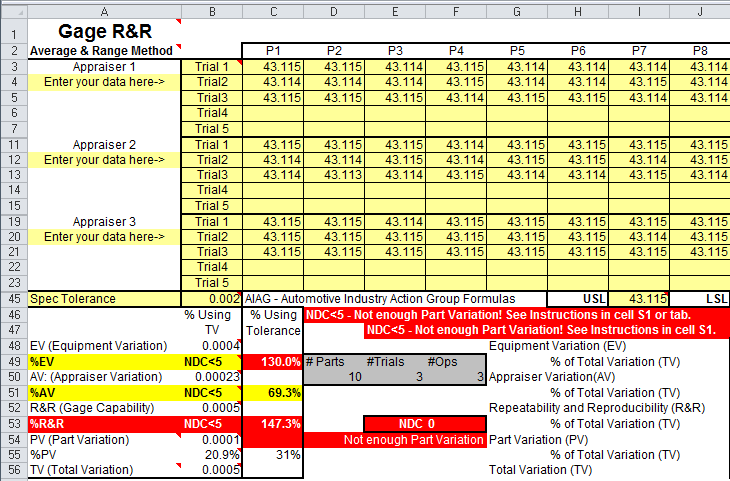

- Calibration checks a tool’s accuracy against standards, while Gage R&R evaluates the measurement system’s overall performance, including the tool, operator, and process.

- Customer-specific requirements may impose Gage R&R, even if it is not a formal standard, so it is important to verify and document customer expectations and ensure compliance with agreed-upon requirements.

In a recent forum discussion, a quality manager shared that their customer failed an audit, claiming that all calibrations should include a Gage R&R to ensure repeatability. The customer’s auditor did not reference any specific standard, leading to confusion. Several experienced contributors clarified that Gage R&R is not a requirement under ISO 9001 for calibrations.

Calibration assesses a tool’s accuracy against recognized standards, while Gage R&R evaluates the entire measurement system, including the operator and environment. Gage R&R is commonly used in measurement system analysis but is not typically required for calibration processes.

Despite the absence of a formal ISO requirement, some customers may have internal policies that require Gage R&R for calibrations, which can cause discrepancies if these expectations need to be communicated. The participants emphasized the importance of verifying customer-specific requirements and ensuring that the quality management system (QMS) is aligned with both ISO standards and customer expectations. It was also recommended that everything be documented for clarity and compliance during audits.

Bottom line: Ultimately, while Gage R&R can be valuable, calibration is not always mandatory unless explicitly required by the customer.

Leave a Reply

You must be logged in to post a comment.