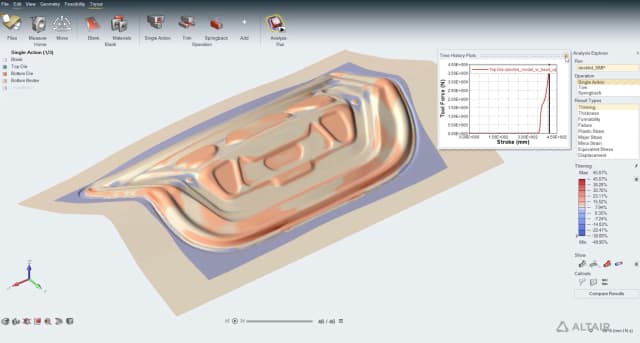

Simulation technology is continually advancing to model increasingly real-world product behavior; however, many companies lag in its adoption.

A recent survey found that only 37 percent of respondents said they applied manufacturing simulation during the product design phase. The vast majority were checking product manufacturability only once the design was completed. Sometimes simulation was used even later after a product failure occurred. Lack of adoption of simulation-driven design for manufacturing (SDfM) is often due to a company’s cost concerns and lack of training and resources, despite managers being cognizant of its advantages.

However, by eschewing SDfM, companies are missing out on the ability to reduce product manufacturing costs, streamline the design process, ramp up production schedules and more efficiently deliver products to customers. These advantages that SDfM provides come amid increasing product complexity and consumer demand for faster time-to-market intervals.

Leave a Reply

You must be logged in to post a comment.