- Improved quality is the primary outcome respondents aim to achieve with existing smart manufacturing technology.

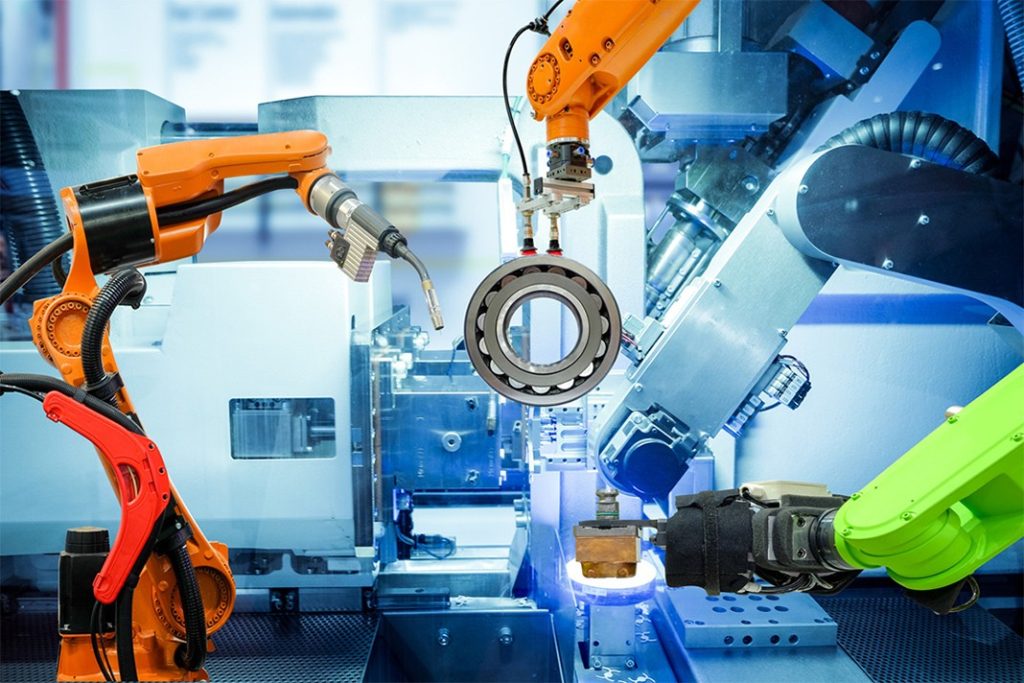

- Smart manufacturing leverages technology and data to optimize operations, improve quality, and increase profitability. Key obstacles include a lack of necessary technology, inadequate supply chain solutions, and cybersecurity risks.

- Adoption of advanced technologies is expected to maintain or increase employment, with a significant impact seen in the Asia-Pacific region.

The “Annual State of Smart Manufacturing Study” by Rockwell Automation emphasizes the transformative potential of smart manufacturing in the digital age. By surveying over 1,350 manufacturers across 13 countries, the report identifies key trends and priorities, highlighting the importance of data in unlocking growth and optimizing operations. Manufacturers are increasingly focused on profitable growth while maintaining high-quality standards, emphasizing leveraging technology to enhance productivity and efficiency.

Despite the benefits of smart manufacturing, significant challenges remain. The report reveals that twice as many manufacturers as in the previous year believe their organization lacks the necessary technology to outpace competitors. Additionally, four out of five manufacturers still lack an end-to-end supply chain planning solution. Cybersecurity risks also rank as a top concern, with manufacturers aiming to mitigate these risks through smart manufacturing initiatives. Improving quality is a major goal, with 45% of manufacturers citing it as the primary positive outcome of adopting smart manufacturing technologies.

The effective use of data is crucial for maximizing the benefits of smart manufacturing. Advanced technologies enable companies to make informed decisions, improve efficiencies, and reduce costs. However, the wide variety of available systems can cause “technological paralysis,” preventing companies from selecting the right solutions. Partnering with experienced advisors is essential for successful implementation and achieving desired results.

The adoption of advanced technologies has a positive impact on employment. The report indicates that 89% of manufacturers plan to maintain or increase jobs due to technology adoption, with 36% expecting to reassign existing staff to new roles. In the Asia-Pacific region, nearly half of the manufacturers plan to adopt smart manufacturing within the next year despite challenges such as employee resistance, skill gaps, and unclear ROI definitions. The quality management system (QMS) has shown the most significant ROI for APAC respondents, followed by manufacturing execution systems (MES) and enterprise resource planning (ERP). The adoption of smart manufacturing in APAC is also driven by its potential as a competitive differentiator, with 88% planning to maintain or grow employment due to technology adoption.

Leave a Reply

You must be logged in to post a comment.