- Five critical components of quality control measures in manufacturing ensure that products meet or exceed the highest standards.

- To effectively implement these quality control measures, the article suggests conducting a comprehensive quality assessment, investing in technology and automation, and providing employee training and skill development.

- Continuous monitoring and improvement through Key Performance Indicators (KPIs), engaging employees in quality improvement initiatives, regularly updating quality control measures, and collaborating with external quality standards organizations are other vital steps highlighted in the article.

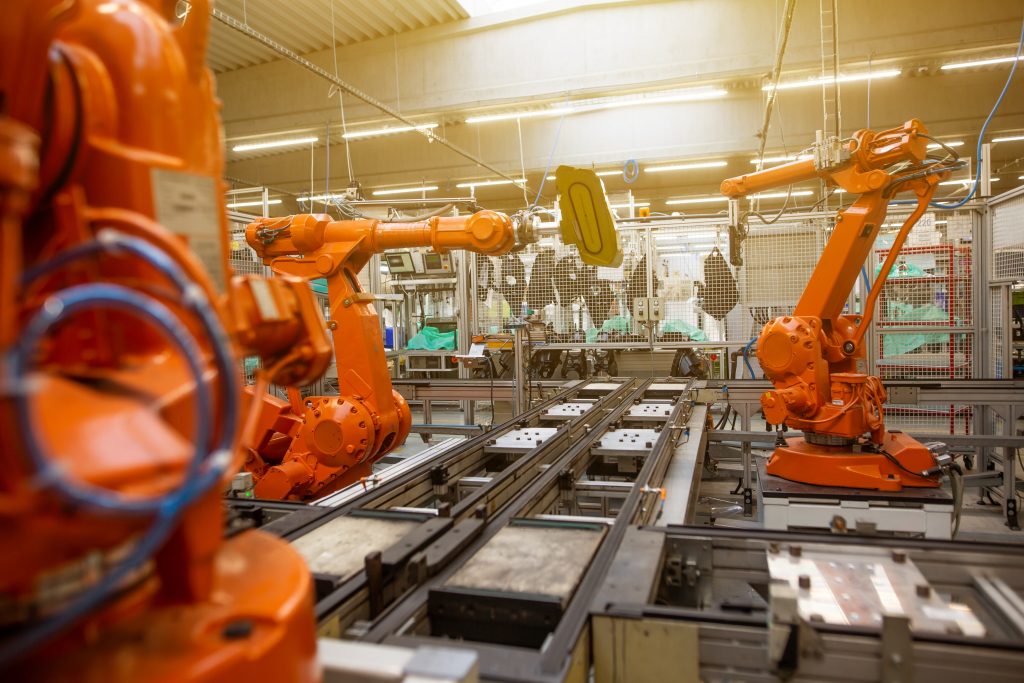

This article from FATFINGER provides a detailed overview of the five critical components of quality control measures in manufacturing. These measures ensure that products meet or exceed the highest standards. The first component, Product Design Analysis, emphasizes collaboration between design and production teams and the integration of Design for Manufacturability (DFM) principles. The second component, Raw Material Inspection, involves establishing clear quality standards with suppliers and conducting regular audits to ensure adherence to these standards.

In-Process Quality Control, the third component, identifies critical control points in the production process and implements real-time monitoring to detect deviations from quality standards promptly. The fourth component, Finished Product Inspection, includes developing a random sampling strategy and comprehensive testing protocols for finished products. Finally, the fifth component, Quality Audits, focuses on scheduling regular internal and external audits and developing corrective action plans based on audit findings.

To effectively implement these quality control measures, the article suggests conducting a comprehensive quality assessment, investing in technology and automation, and providing employee training and skill development. Establishing clear Standard Operating Procedures (SOPs) and implementing a closed-loop feedback system are also vital. Continuous monitoring and improvement through Key Performance Indicators (KPIs), engaging employees in quality improvement initiatives, regularly updating quality control measures, and collaborating with external quality standards organizations are other vital steps highlighted in the article. Overall, these strategies form a robust framework for achieving manufacturing excellence.

Leave a Reply

You must be logged in to post a comment.