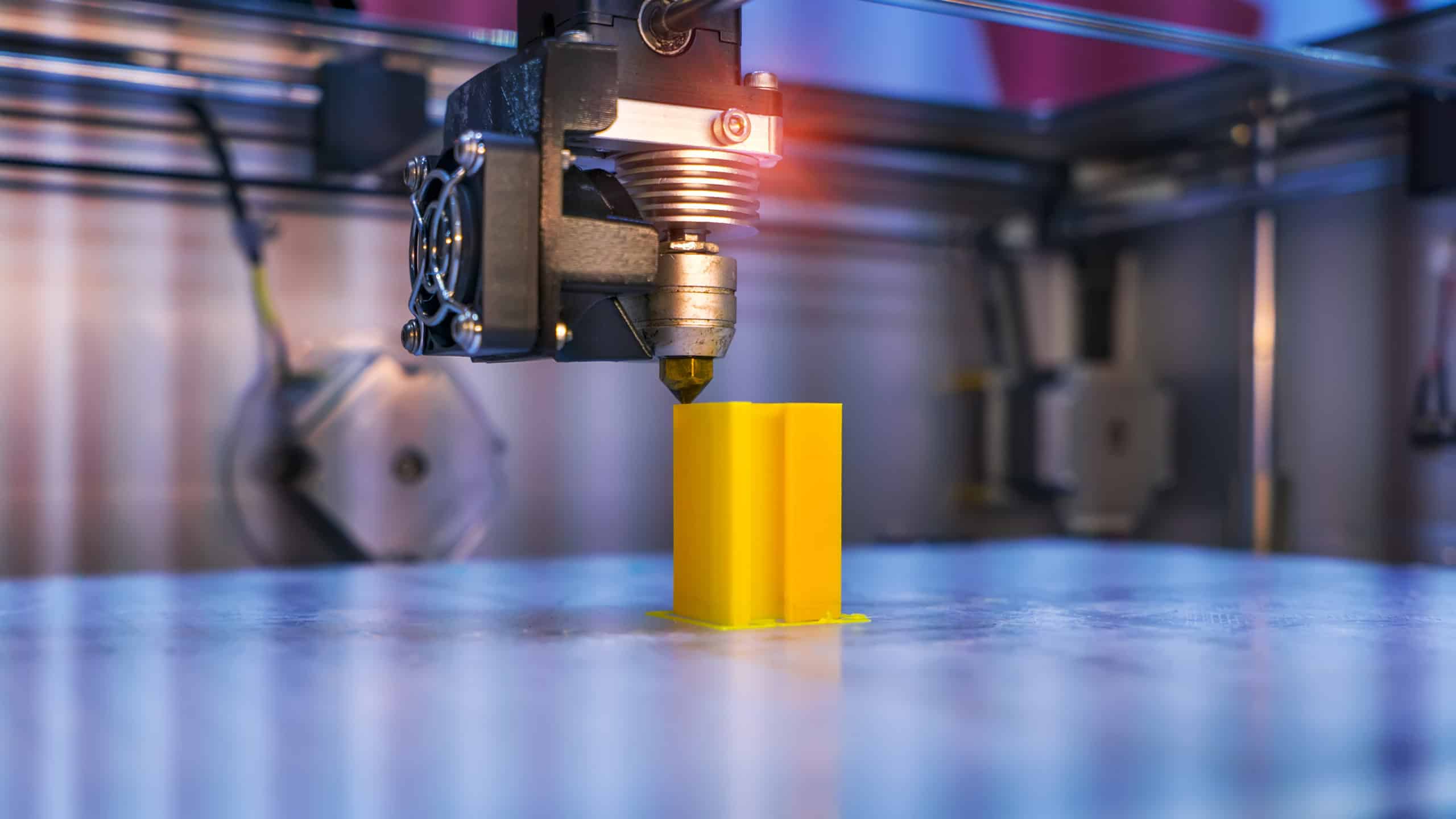

This article from Metrology News looks into the significance of quality validation in additive manufacturing (AM). As AM, commonly known as 3D printing, continues to gain traction across various industries, ensuring the quality and reliability of printed components becomes paramount. AM’s unique layer-by-layer construction method introduces potential inconsistencies and defects that traditional manufacturing methods might not encounter.

Quality validation in AM involves a multi-faceted approach. First, there’s the need for in-process monitoring, where sensors track the printing process in real time, identifying potential anomalies or deviations from the intended design. This proactive approach can help detect issues early, reduce wastage, and ensure the final product’s integrity. Post-process validation is equally crucial, where advanced techniques like computed tomography (CT) scanning are employed to inspect the internal structure of printed components, ensuring they meet the required specifications and standards.

The article underscores that as AM technologies evolve and their applications expand, the tools and methodologies for quality validation must also advance. By integrating sophisticated monitoring and validation processes, industries can harness the full potential of additive manufacturing, producing high-quality, reliable components that meet the demands of modern applications.

Leave a Reply

You must be logged in to post a comment.